Health & Safety Policy

XMC Safety Health and Environment Policy

-

01

Complying with ESH regulations and international protocols.

-

02

Continually improving ESH system and providing necessary resources.

-

03

Ensuring safety and health of our employees and enhancing environmental quality as the primary responsibilities of every manager.

-

04

Enhancing workplace ESH management through area ownership.

-

05

Enhancing employees ESH competence and awareness.

-

06

Implementing workplace ESH inspections and eliminating safety and environment hazards, improve energy performance, and reduce adverse environment impacts.

-

07

Strengthening emergency response and recovery capabilities.

-

08

Exploring and practicing energy saving and emission reduction methods,establishing a green supply chain, implementing green design and manufacturing,to provide customers green products,and to realize continuous green developments.

All our employees shall implement their ESH obligations as required at all times.

- 1.1 Pollutant emission control

-

We endeavor to reduce pollutant emission by employing state-of-the-art pollutant disposal and control technology and implementing whole-process pollutant control. Since the establishment of the Company, the pollutant emission concentration has always been controlled at a low level within the standard requirements of national laws and regulations.

(Environmental information disclosure website: http://219.140.164.18:8007/hbyfpl/frontal/index.html#/home/index)

- 1.2 Energy consumption control

-

XMC implemented three rounds of clean production audit from 2009 to 2020. It passed the first round of clean production audit in October 2010 and the third round of clean production audit in September 2020. From 2009 to 2020, XMC has implemented 79 clean production programs, continuously attaining the clean production audit targets published by the government. XMC has continuously discharged its responsibility as an energy-efficient entity by strengthening energy conservation measures and improving energy efficiency. We completed the targets of "double control" of total energy consumption and energy intensity for the “13th Five-Year Plan” period published by the government every year from 2015 to 2020. XMC will continue to practice energy-efficient strategies and improve the energy-using environment to achieve win-win for both the Company and the society.

- 1.3 Hazardous substance control

-

XMC pays close attention to the control of hazardous substances in products, has established and implemented the hazardous substances process management system, and attained QC080000 certification. Backed by green supplier evaluation mechanism and hazardous substance risk and opportunity assessment initiatives, we manage to control hazardous substances from the source and put them under strict control throughout the production, and implement whole-process management of hazardous substances internally and externally, so that the products can meet the domestic and international hazardous substance control standards and are more sophisticated and eco-friendly.

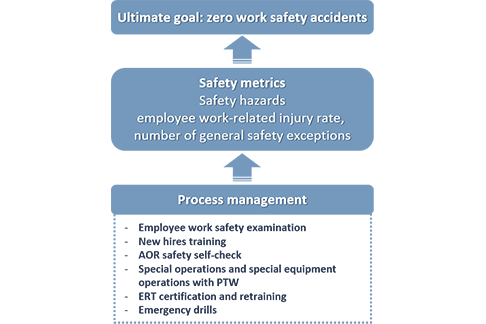

- 2.1 Accident and work-related injury prevention

-

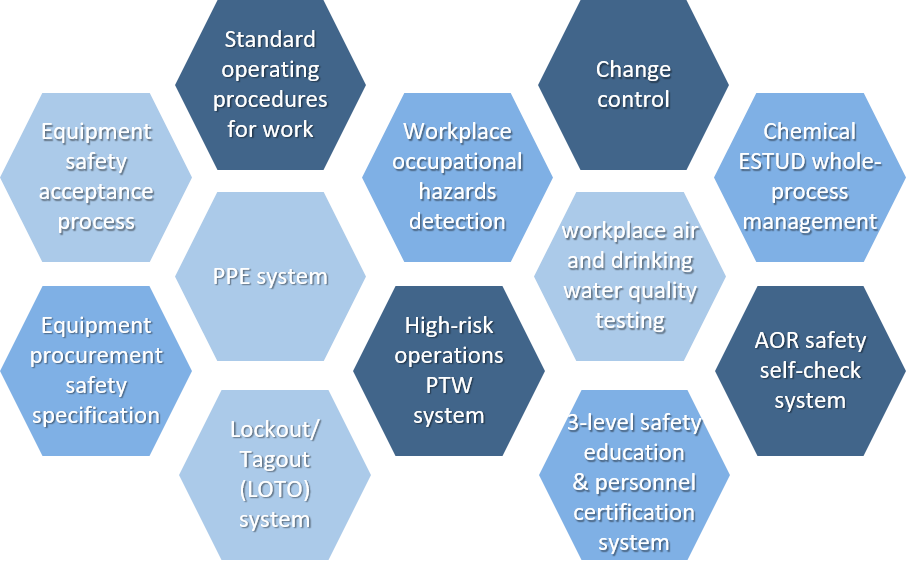

XMC has developed a standardized and sound accident and work-related injury prevention process and system:

- Equipment safety acceptance process, and equipment procurement safety specification

- Standard operating procedures for work, high-risk operations PTW system, PPE system, Lockout/Tagout (LOTO) system

- Workplace occupational hazards detection, and workplace air and drinking water quality testing

- Change control, and chemical ESTUD whole-process management

- 3-level safety education and personnel certification system, and AOR safety self-check system

- 2.2 Work safety education and training

-

XMC has established a comprehensive safety education and training system for employees, covering:

- 3-level safety education for new hires

- Annual mandatory safety and occupational health training courses

- Quarterly retraining and certification of safety rules and regulations

- High-risk operations certification

- ERT certification and retraining

- First-aid knowledge training and certification

- Annual Safety Month quality courses

- Off-job safety retraining for violators

- 2.3 Occupation health and employee care

-

XMC pays attention to and cares for the life safety and physical and mental health of every employee. We have set up a professional medical rescue institution, Health Center, where experienced medical staff provide 24-hour free medical services and emergency medical assistance to employees. We strive to improve employees' first aid capacities and popularize health knowledge and concepts by launching annual Health Month activities, carrying out cardio-pulmonary resuscitation (CPR) and automated external defibrillator (AED) first aid training and competitions and organizing health lectures and voluntary clinics activities. In addition, we provide free on-the-job occupational medical examination for all employees exposed to occupational hazards and annual health examination for general employees, so as to offer every employee life and health care.

- 2.4 Safety campaigns

-

June is established the Safety Month of XMC, and we promote EHS concepts through various activities to enhance employees' safety awareness and skills, with an annual average of more than 1,100 participants in safety-related activities.

-

ISO14001

XMC attained ISO14001 certification in March 2009. ISO14001 is a voluntary international standard that establishes requirements for a world-class environmental management system. With this system in place, we can ensure its responsible use of energy and materials through improvements in recycling, waste reduction and pollution prevention.

Download

-

ISO45001

XMC attained ISO45001 certification in March 2009. ISO45001 is a key component of a corporation's total health and safety management and is based on international safety and health standards.

Download

-

QC080000

QC080000 certification in March 2010. QC080000 is an effective system that ensures products contain hazardous substance free to comply with customer's requirements and relevant laws and regulations.

Download

-

Sony Green Partner

In December 2015, XMC obtained the "Sony Green Partner" certificate and officially became a partner of Sony's green supply chain.

Download

-

ISO14064

XMC attained ISO14064 verification in November 2010. ISO14064 is the method to calculate greenhouse gas discharging quantity in order to pursue the goal of reducing greenhouse gas quantity.

Download

-

ISO50001

XMC is committed to reducing greenhouse gas emissions, practicing clean production and green development, and passed the ISO50001 energy management system certification for the first time in 2019.

Download